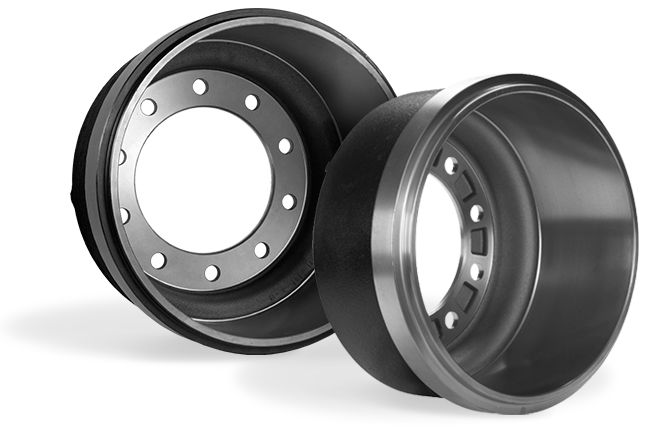

BRAKE DISCS, DRUMS & HUBS

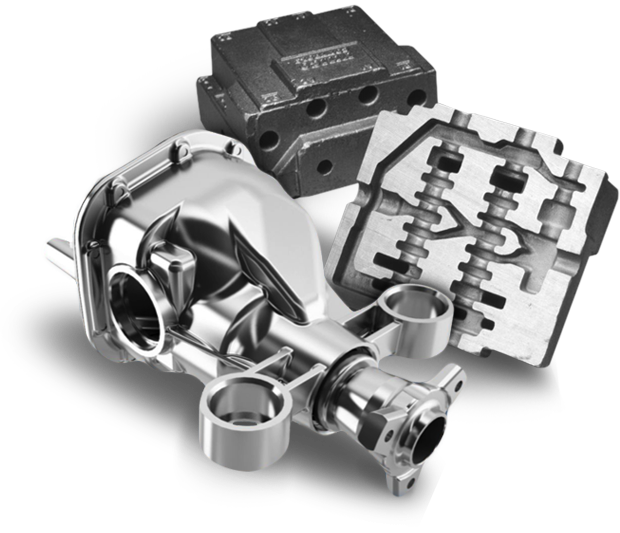

With over half a century of experience supplying the automotive industry, MAT Foundry Group specializes in the casting, machining and distribution of a variety of brake carriers, discs, drums, and hubs for commercial vehicles and trailers. MAT Foundry Group maintains 7 foundries across 3 continents with a capacity of over a half a million tons per year. MAT Foundry Group also maintains 12 machining centers to support turnkey product availability. We employ a highly-skilled workforce and a strong team of engineers who work closely with our OEM customers from concept through to delivery.